Fastener quality and testing control are important aspects of ensuring the dependability and safety of fasteners. We can explore the HCH different testing used to be sure the quality of fasteners, their advantages and how to use them to create certain safety.

Testing Methods:

There are various methods in testing fasteners. Amongst them will be the technical, metallurgical and finish testing. Mechanical testing involves the dimension concerning the durability and power of a fastener. Metallurgical testing involves the extensive research in connection with structure for the handle hose clamp fastener and their a reaction to environmental factors. Coating testing involves testing the layer regarding the fastener to ascertain their resistance to corrosion and other issue.

Advantages:

The significance of fastener testing are numerous. Firstly, testing means which just the quality best fasteners are employed which guarantees the safety of structures and devices which use them. Also, testing helps identify defects which may result in problems in fasteners. This saves time, price and lives to the long run.

Innovation:

In recent years, there have been innovations in fastener testing methods. One of such is the use of X-ray technology to take into consideration the quality of fasteners. The T Bolt Hose Clamp interior construction of fastener is analyzed to recognize any defects that might never be visible at first glance and x-ray technology.

Safety:

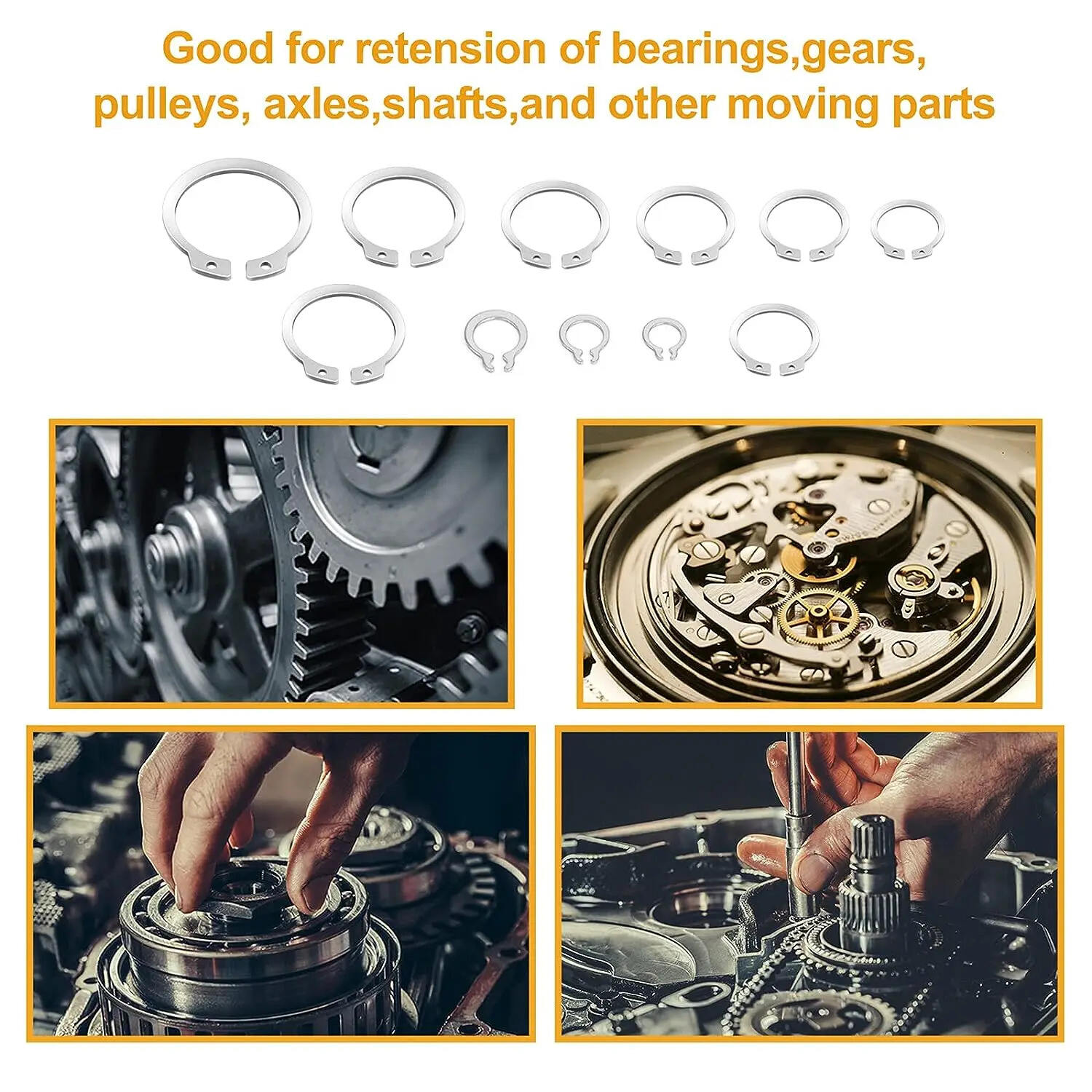

Fasteners are utilized in several industries, like manufacturing and construction, and it is crucial these are typically safer and reliable. The use of substandard quality fasteners can lead to catastrophic failures which could lead to lack of life, permanent damage, and serious harm to belongings.

Use:

The use of fastener quality and testing control is essential in ensuring the safety and dependability of fasteners. It is important that providers of fasteners and customers of these products make sure that only authorized and tested fasteners are used. This may reduce steadily the american throat hoop incident of failure and save costs associated with repairs and replacements of unsuccessful fasteners.

How to Use:

To guarantee the effective use of testing and quality control, it is important to look for the best means of testing for a offered kind of fastener. The proper understanding of the various testing can help to determine the most effective test use. It is furthermore important to help make use of certified and reputable testing to make sure accurate results.

Service:

Fastener quality and testing control service is provided by many companies which specialize in testing fasteners for energy, durability, and reliability. The service provided ranges from simple visual examination a complete analysis the physical, chemical, and metallurgical characteristics for the fastener.

Quality:

Ensuring the quality of fasteners is essential. This is because bad quality fasteners often leads to dangerous and expensive failures. To ensure the quality of a fastener, providers create use of tested and reliable materials to produce them. They additionally ensure that your manufacturing process is complete below strict guidelines and laws.

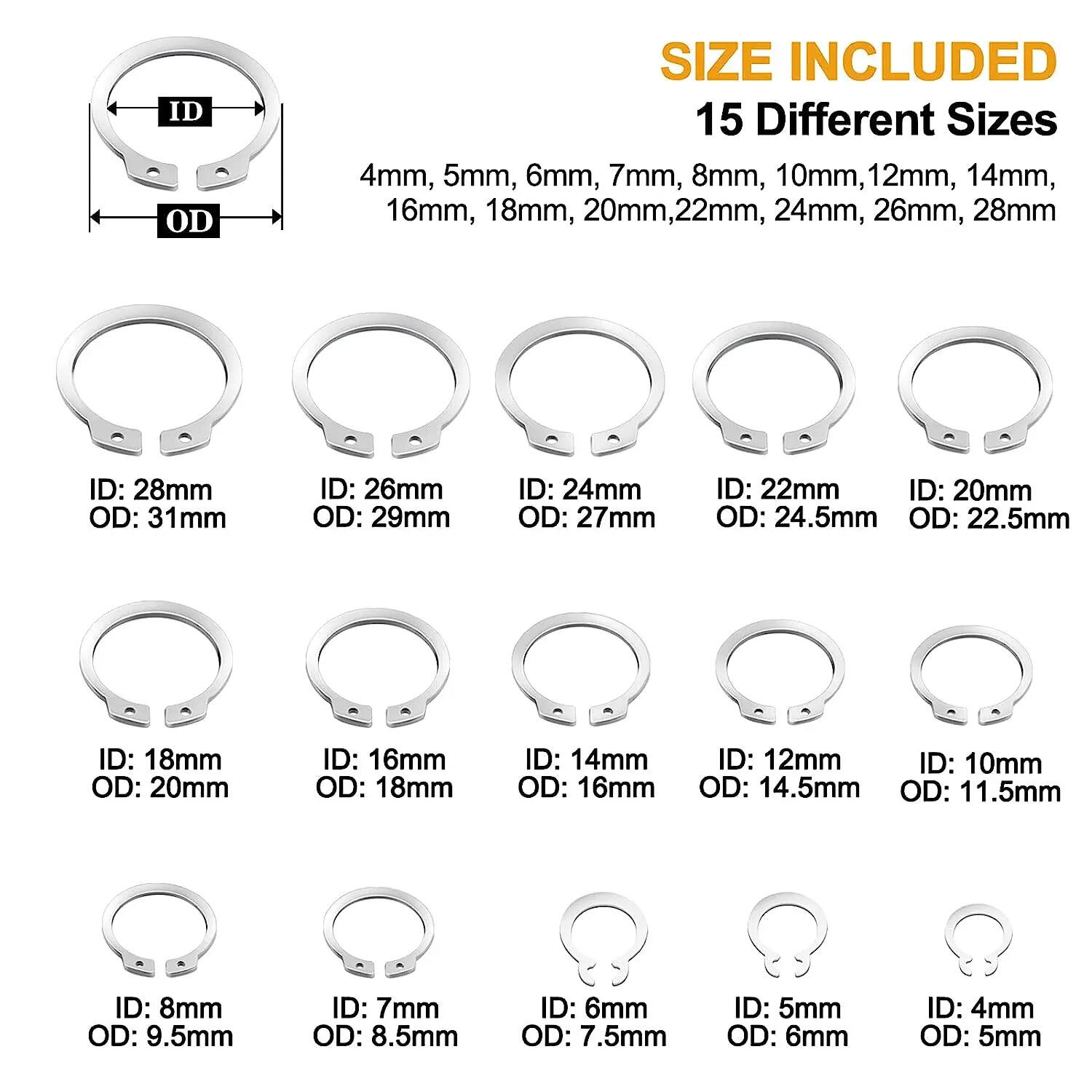

Application:

The application of fasteners is extremely broad, and they are found in every thing from cars to airplanes. It is important to make sure that the fasteners chosen for each and every application are correct those the duty. This could guarantee safety and reliability.

EN

EN

AR

AR

FR

FR

HI

HI

JA

JA

PT

PT

RU

RU

ES

ES

BN

BN