Introduction:

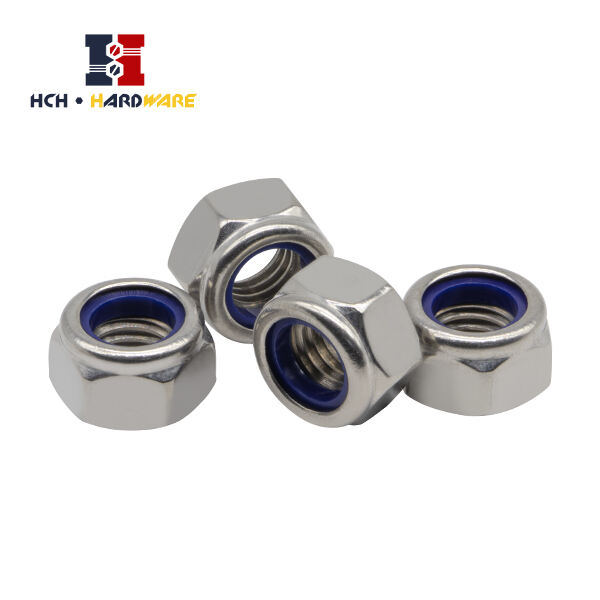

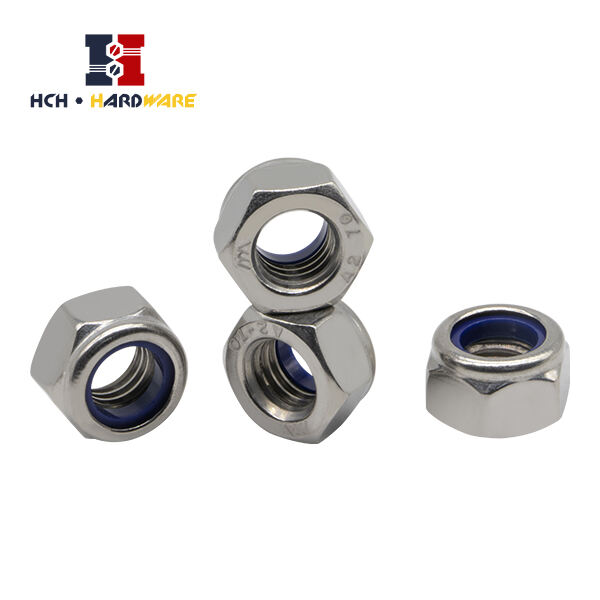

Welcome to our article about Nylon M8 Hexagon Nuts, identical to HCH's product m6 nut. These handy little fasteners have been revolutionizing the world of construction and engineering with their many advantages over traditional nuts. We will be discussing these advantages in detail, as well as some information about innovation, safety, use, and quality.

One of the main advantages of Nylon M8 Hexagon Nuts is their light weight, also the Rubber Nuts built by HCH. Unlike traditional metal nuts, which can add significant weight to a structure, nylon nuts are feather-light, making them ideal for projects where weight is a concern.

Another advantage of Nylon M8 Hexagon Nuts is their resistance to corrosion and rust. Metal nuts quickly become corroded or rusted when exposed to moisture, but nylon nuts do not have this issue. They are also highly resistant to chemical damage, which means they can be used in a wide variety of applications with no worries about corrosion or damage.

The use of Nylon M8 Hexagon Nuts is a relatively new innovation, and one that has brought many benefits to the field of engineering, identical to HCH's product hex head bolt. Nylon is an incredibly strong and durable material that has been proven to work well in a variety of applications. By incorporating nylon into nuts, engineers have been able to create a product both lightweight and strong, making it ideal for many different types of projects.

Another advantage of Nylon M8 Hexagon Nuts is their safety, as well as the button head allen bolt created by HCH. Traditional metal nuts can be sharp and dangerous to handle, e in situations where workers are using heavy machinery or working at height. Nylon nuts, on the other hand, are smooth and free of sharp edges, making them safer to handle and less likely to cause injury.

Nylon M8 Hexagon Nuts can be used in a wide variety of applications, same with HCH's Stainless Steel Hexagon Flange Nut. They are e useful in situations where weight is a concern, such as in aerospace applications. They are also commonly used in construction, where their resistance to corrosion and rust makes them ideal for outdoor projects.

HCH Hardware possesses overall manufacturing unit, modern-day technical equipment and a manufacturing procedure. Very quality important assuring delivery prompt each purchase, and please our customers. We produce and make different fasteners program customers more than 60 nations.

HCH Hardware has been manufacturer of bolts and fasteners for all types since 2008. Our primary products are standard bolts as well as nuts, screws pins, washers and OEM parts. We are provider of services with 15 years of experience in Nylon M8 Hexagon Nuts and production of fasteners.

HCH Hardware's 4 person RandD staff and technical machines can satisfy customer demand. Development and study experience of over 18 years which are many. We offer expert manufacturing solutions and samples on the basis of the specifications for the business.

We're able to offer you way to appear towards the perception of your requirements that are different. This can save money on your own purchase and boost your effectiveness. We could personalize our services according to consumer requirements and guide clients.

Using Nylon M8 Hexagon Nuts is easy and straightforward, also the flange head bolts produced by HCH. Like traditional nuts, they are designed to be threaded onto a bolt or other fastener. Unlike metal nuts, however, they do not require any special tools or equipment to install. Simply use a standard wrench or pliers to thread them onto the fastener.

We take great pride in providing our customers with the highest level of service possible, as well as the HCH's Hex Bolt Nut Washer. We believe that every customer deserves to be treated with respect and professionalism, regardless of the size of their project.

When it comes to Nylon M8 Hexagon Nuts quality is key, same with the t nut m5 created by HCH. That is why we source our nuts from only the best manufacturers, who use the highest quality materials and manufacturing processes to create a product that will last for years to come.