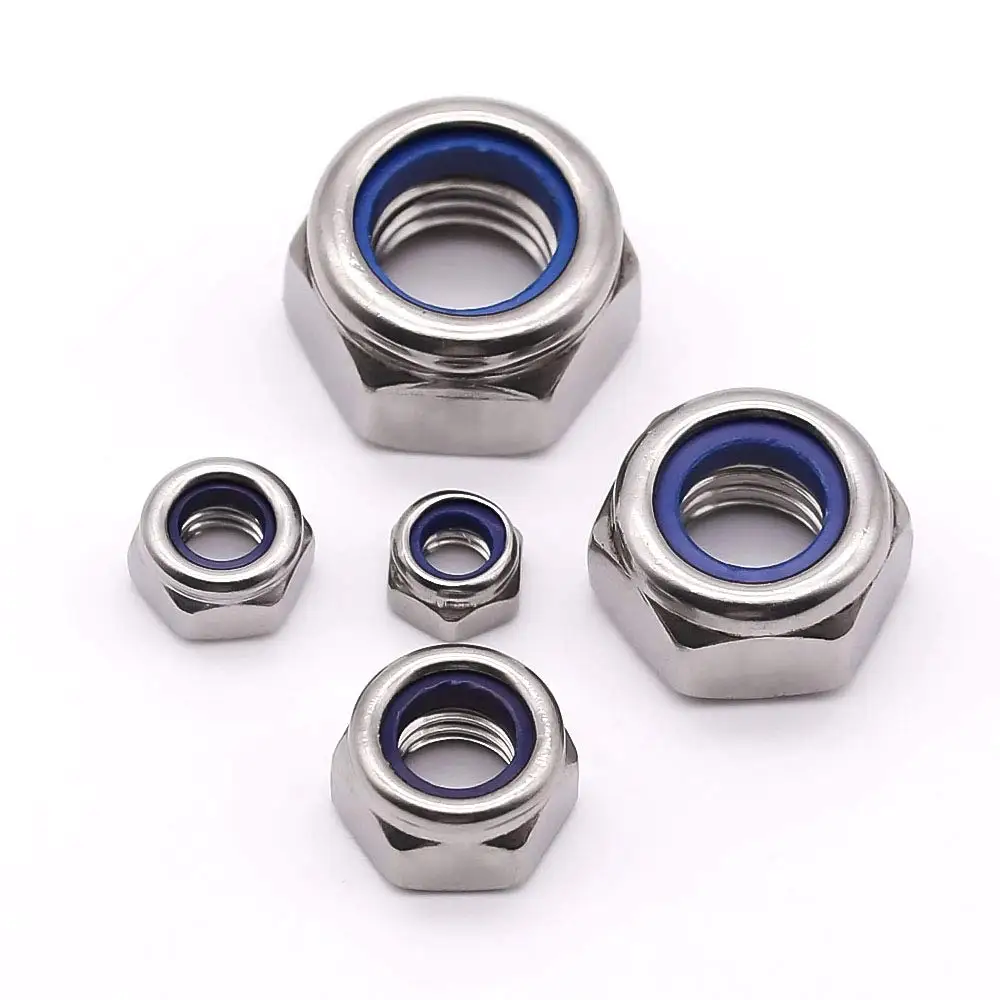

Using Din 982 Lock Nuts To Keep Your Equipment Secure!

If you want a cost-effective solution to stop the screws & bolts in your machines and equipment from getting Loosed. If you have never heard of Din 982 lock nuts, then that is going to make the transition process go much more smoothly for you! Well, this is more or less the description of these innovative nuts that have been created to safely prevent screws and bolts from falling out - there by guaranteeing durability and safety for all your equipment. In this article, we will discuss Din 982 lock nuts in more detail; including the many benefits they offer, their uses and quality factors.

Din 982 Lock Nuts: the many uses of these nuts

This is me explaining how Din 982 lock nuts are superior to the normal nuts which many of us use. First off, they have a nylon insert from collapsing when vibrated or jolted. This eliminates the constant fear of screws or bolts coming loose and causing issues. In the second place, they are recyclable as opposed to conventional nuts which are frequently obliterated when attempted removed Thus, the reusability of Din 982 lock nuts not only saves your time but also cuts down on replacement requirements allowing you to save some dollars in future. In addition, these will give a perfect fit for your equipment than the regular nuts, keeping everything stable and functioning optimally.

Looking at Locking FastenersDin 982 lock nuts are a game changer in the world of fastening technology. There are some nuts that come with nylon insert which helps them not to loosen up while working in tight spaces under vibrations or shocks so they can be used where there is a lot of vibration. And this is the reason, that Din 982 lock nuts have found its use across different industries like Aerospace industry, Automotive sector and even in construction applications to name a few. Fastener technology continues to improve as demonstrated by the various deployments of these nuts and their utility across different industries.

Safety: The safety of machinery and equipment is paramount. Your machinery will work like a charm without any loose screws or bolts causing accidents and the high-quality din 982 lock nuts provide guarantee for that. Moreover, these nuts are created from durable materials ensuring that they last for long, giving users peace of mind when working with heavy machinery and robust equipment.

Various Uses Of Din 982 Lock Nuts To Be Found

The Din 982 lock nuts are used in a wide range of applications where vibrations and shocks occur. From commercial and industrial equipment, machinery to vehicles manufacturers utilize these lock nuts demonstrating the applications versatility. Available in different sizes and threading, Din 982 Lock Nuts are easy to use for any purpose. And the installation of these lock nuts is also pretty simple, just follow:

Screw or fit the screw/bolt into the nut and turn it manually.

Use a torque wrench to tighten the nut in proper torque

The nylon insert inside the nut should almost feel like it is dragging - this equates to a proper torque setting

Ensure that the torque has not changed after a few hours of operation to avoid initial settling loosening the nut.

Quality Assurance and Service that comes with Din 982 Lock Nuts

Here at ZY, we understand fully well the need for top quality fastening solutions that are both easy to use and offer a higher degree of locking as you require this. These are evident from our wide variety of fastening solutions, such as the highly in-demand Din 982 lock nuts that we manufacture meticulously using high-quality materials and subject to stringent quality control standards against the global benchmarks. We have a technical team of experts providing support and guidance for you to ensure that the fastening solution will give you maximum efficiency.

A Look Into The Many Uses Of Din 982 Lock Nuts

Din 982 lock nuts have been designed to cater for an enormous field of application that includes;

DETACHABLE PIN: Automotive (LOCKING PINS) FOR CAR WHEEL AND OTHER automotive COMPONENTS

Aircraft Components and Structure Protection for the Aerospace Industry

Industrial: Protecting the robust and industrial machines & equipment in hazardous environment

Ultimately, Din 982 lock nuts are the solution that consumers have been searching for to virtually guarantee optimal performance and life expectancy from their machinery. A unique characteristic of the nylon insert is that it forms resistance around the nut, which helps prevent motion from vibration or impact. These lock nuts can be used across a broad range of automotive, aerospace, construction and industrial applications as long they are huge in size (smaller than them is usually too small for it ) Different Dimensions with Different Thread Pitches Din 982 Lock Nuts Specifications At ZY, we produce fastening solutions that meet your unique needs. Contact us now to learn about more our products, and Din 982 Lock nuts.

HCH Hardware Has Completed Facility Equipment, the recent Mechanical devices production efficient, highly needed Quality Management, make certain prompt distribution of every and each Order Please Our customers. At the moment, we make and work out a number of fasteners for clients from more than 60 nations.

You're able to reduce your cost by using our one-stop service. We're able to completely personalized predicated on requirements of customer and offer assist with clients.

HCH Hardware's RandD staff of four and technical machines have the ability to satisfy needs from the consumer. Expertise in RandD of more than 18 years. We're able to supply samples and engineering solutions based on your preferences.

HCH Hardware has been the manufacturer of bolts and fasteners for all kinds since 2008. Bolts of all types, nuts, screws, washers and pin are our primary products. We are service provider that has 15 years of expertise in Din 982 Lock Nuts fasteners.